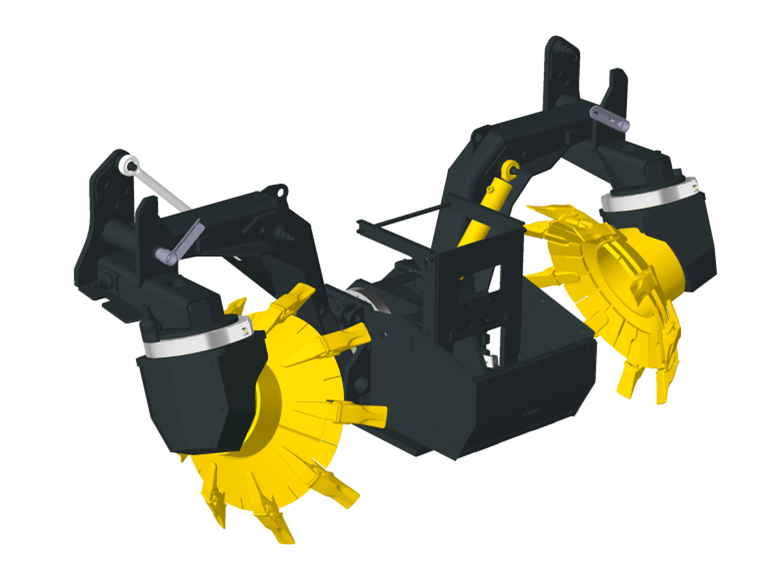

The Plantma-X is a machine that is adapted to Swedish conditions, scarifying with a disc, coping with many rocks in the ground, planting primarily spruce or pine in fairly small pots, distance between plants 1,6- 2 meters etc. etc.

Many parts of the world might have flat ground not so many rocks etc. and can therefore use a simpler machine, or another brand of machine, as a carrier for the planting arms.

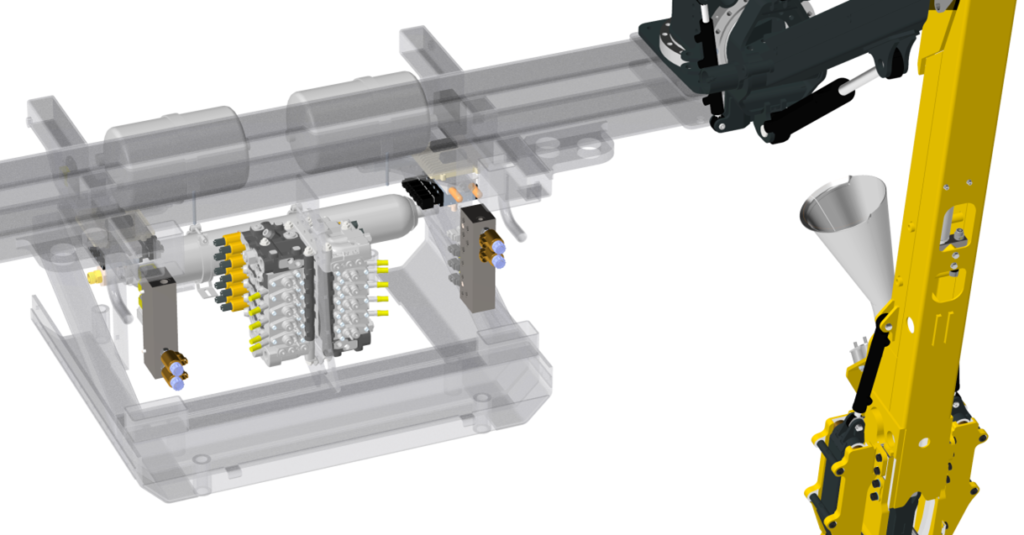

Very likely, the Plantma-X is too sophisticated, and thus too expensive, for many markets. Therefore we have decided to offer the arms and the control systems, mounted in/on a frame, as a “Base kit”, which includes:

Hydraulics: The frame is delivered with all hydraulic valves that are needed to run the planting arms as well as an accumulator that reduce the peak-loads. All hoses that are needed from the valve banks are connected to the arms. What you need to connect are the hoses to the carrier, pressure, tank and drain line.

Compressed air: All necessary valves and hoses, as well as an air tank, are included in the frame.

Must be connected to the carrier.

Control system: All sensors are connected. The display and button pads can be included but need to be plugged into the system

What then has to be solved locally is:

- Scarifier or no scarifier? Naturally we can supply a Midiflex scarifier if needed

- How to feed the plants to the planting arms. We can supply the arms with the “cups” that feed the seedlings to the arm

- The cab for the operator of the planting device,

- The storage bin for the seedlings on the tractor and

- The crane to load the storage bin

The idea of us delivering the arms and control systems as a package from us and then having the machine mounted locally has many advantages:

- The carrier can be of a preferred brand, or even manufactured locally, adapted to the local conditions and market expectations. There are many ways to configure the complete machine, scarifier / no scarifier, distance between arms, how to feed the plants to the arms, water for each plant (requires a big tank), fertilizer for each plant and so on.

- Much of the needed repair/service skills are available close to the machine as well as most spare parts.

The following specifications apply for the planting arms. If the machine is to be equipped with a scarifier, please see the manual for hydraulic needs for that equipment.

Plantma-X: Hydraulic system (Tree planter) | |

| Type: | Load sensing, LS line |

| Working pressure: | 135 bar (net 105-110 bar + Dp/standby) |

| Average flow (2500 pl / h – 100% hit): | 50 l / min |

| Average flow (2500 pl / h – 85% hit): | 53 l / min |

| Max peak flow requirement / 1 planter: | 100 l / min |

| Max peak flow requirement / 2 planter: | 150 l / min |

| System loading: | Auto charging system accumulator via pressure sensor, 90 bar |

| Unloading: | Discharge of accumulator via drain valve when unloading |

| Hydraulic average power: | 12 kW (2 planters) |

| Hydraulic peak power: | 34 kW (2 planters) |

| Engine average power: | app. 15 kW (2 planters) |

| Engine peak power: | app. 42 kW (2 planters) |

Plantma X: Pneumatic system (Tree planter) | |

| System pressure: | 7-8 bar |

| Flow consumption: | Max 750 l/min (free air delivery for 2 planters) |

Basic “kit”

Is this necessary? Well, that depends on the requirements of the land-owner.

We can supply the complete unit including the control system and button pads.

For hydraulic requirements and more information about MidiFlex please visit:

http://alftaprodukter.se/midiflex/